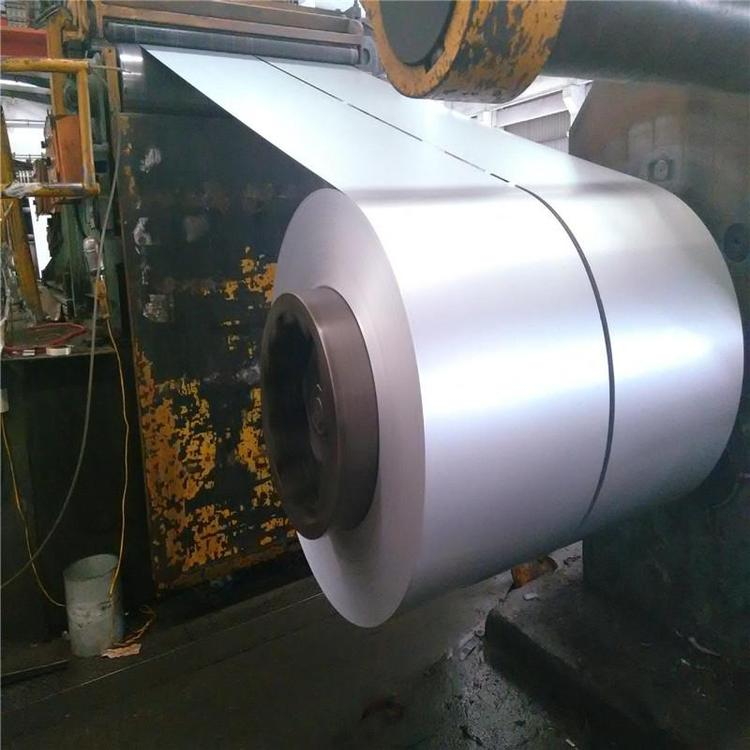

AYHS5 Cold Rolled Steel Coil

Cold rolled coil takes hot-rolled steel coil as raw material and carries out cold continuous rolling after acid pickling to remove oxide scale.

Cold rolled coil takes hot-rolled steel coil as raw material and carries out cold continuous rolling after acid pickling to remove oxide scale. Its finished product is hard rolled coil. Due to the cold work hardening caused by continuous cold deformation, the strength and hardness of hard rolled coil increase and the toughness and plasticity index decrease. Therefore, the stamping performance will deteriorate and can only be used for simple deformed parts. The hard rolled coil can be used as the raw material of the hot-dip galvanizing plant, because the hot-dip galvanizing units are equipped with annealing lines. The weight of rolled hard coil is generally 6 ~ 13.5 tons. The hot-rolled pickling coil is continuously rolled at room temperature. The inner diameter is 610mm.

Product FeaturesBecause it has not been annealed, its hardness is very high (HRB greater than 90) and its machining performance is very poor. It can only carry out simple directional bending less than 90 degrees (perpendicular to the coiling direction).

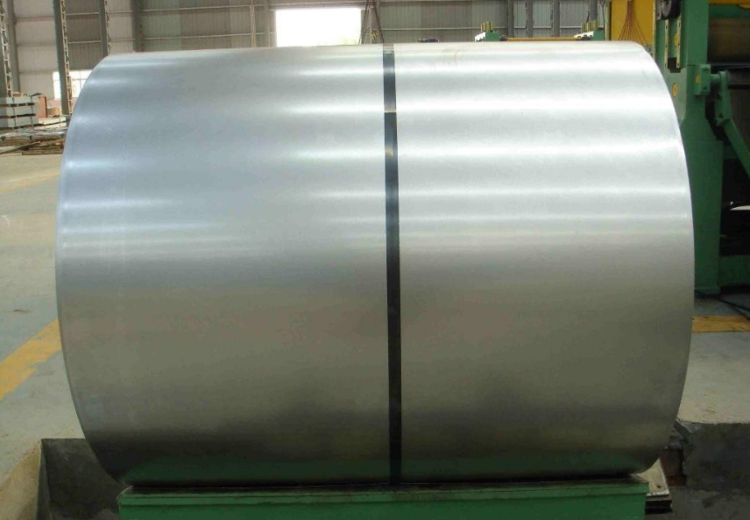

ApplicationCold rolled coil is widely used, such as automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, food cans, etc. Cold rolled thin steel coil is the abbreviation of cold rolled coil of ordinary carbon structural steel, also known as cold rolled coil, commonly known as cold coil, which is sometimes mistakenly written as cold rolled coil. Cold coil is a steel coil with a thickness of less than 4mm made of hot-rolled steel strip of ordinary carbon structural steel after further cold rolling. Because it is rolled at normal temperature and does not produce iron oxide scale, the cold coil has good surface quality and high dimensional accuracy. Combined with annealing treatment, its mechanical and technological properties are better than hot-rolled steel coil. It has been gradually used to replace hot-rolled steel coil in many fields, especially in the field of household appliance manufacturing.

IntroduceCold rolled coil (annealed): it is obtained by Bell annealing of cold and hard coil before rolling. After annealing, the work hardening phenomenon and internal stress are eliminated (greatly reduced), that is, the yield strength is reduced close to that before cold rolling.

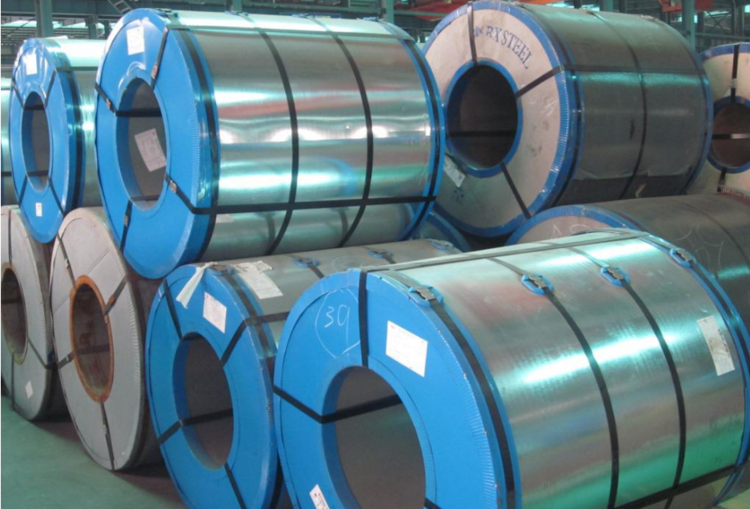

ClassificationCoil plate is a kind of plate in steel. In fact, it is a long and narrow thin steel plate supplied in coils. Coil and flat plate are almost a cutting package

Difference between cold rolling and hot rolling1. In appearance, the cold and hard coiled plate is a little dark.

PRODUCTS

CATALOG

We understand that this catalog may not answer all your questions. Please contact us , we will be happy to help you. Our goal is to return a quote to you within 24 hours.

Contact

Us

ID

Scan QR code add