HC260Y is a high strength steel without interstitial atoms. The chemical composition of the steel is controlled to improve the plastic strain ratio (r value) and strain hardening index (n value). Due to the solid solution strengthening of elements in steel and the microstructure without interstitial atoms, this kind of steel not only has high strength, but also has very good cold forming properties. It is usually used to make complex parts that need deep stamping, which are widely used in ships, vehicles, aircraft, railways, bridges, pressure vessels, machine tools and other structures.

Chemical composition range value:

The actual chemical composition shall be subject to the warranty of the steel plant.

Hc260y carbon C: ≤ 001

Hc260y Mn: ≤ 2.00

Hc260y sulfur s: ≤ 0.12

Hc260y phosphorus P: ≤ 0.025

Hc260y all aluminum at: ≥ 0.010

Hc260y titanium t ≤ 0.12A

It is allowed to replace Ti with Nb in part or in whole. At this time, the total content of Nb and / or Ti shall not be greater than 0.20%.

Hc260y mechanical property range value:

Note: the actual force word performance shall be subject to the warranty of the steel factory.

tensile strength σ b(MPa) : ≥380

yield strength σ 0.2(MPa) : 260-320

Elongation a80mm (%): ≥ 28

Sample size: the Gross size of the sample is 1.3mm

Production process:

Due to no heating, there are no pitting and scale defects in hot rolling. The surface quality is good and the surface finish is high. Moreover, the dimension precision of cold rolled products is high, and the properties and structure of products can meet some special requirements, such as electromagnetic properties, deep drawing properties, etc.

Performance: mainly made of low carbon steel, with good cold bending and welding performance, as well as certain stamping performance.

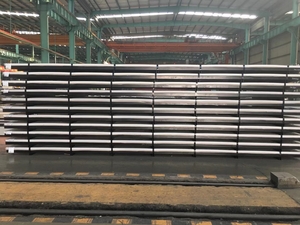

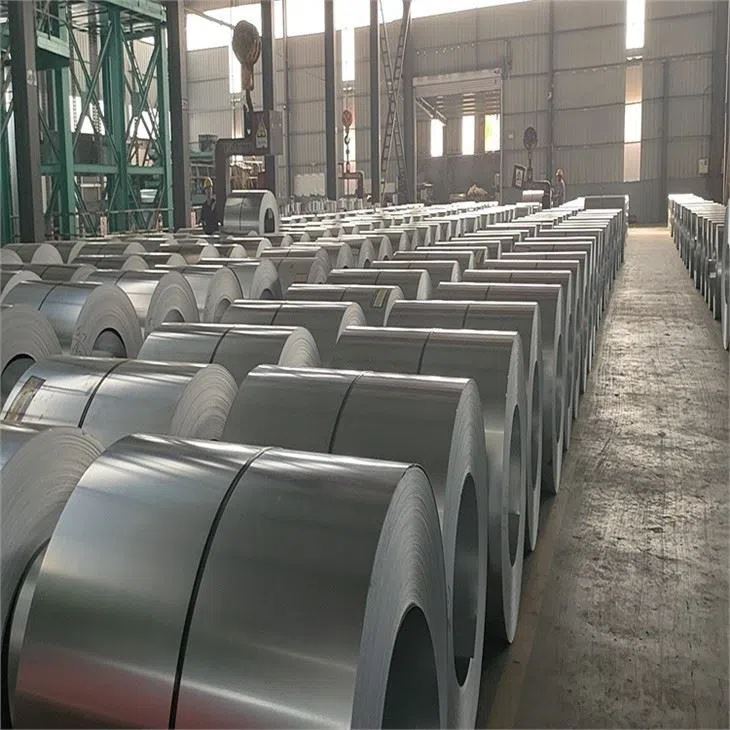

1, cold rolled coil thickness more accurate, smooth surface, beautiful, but also has superior mechanical properties, especially machining performance.

2. The maximum thickness of cold-rolled steel coil is less than 0.1-- 8.0mm, such as the thickness of cold-rolled steel coil in most factories is less than 4.5mm;The minimum thickness and width are determined according to the equipment capacity and market demand of each plant.

3, cold rolled steel mill power, low rolling efficiency, and the rolling process in order to eliminate the work hardening have to carry out intermediate annealing, so the cost is higher, but cold rolled steel surface bright, good quality, can be used to process finished products, cold rolled steel is widely used.

Specification

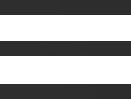

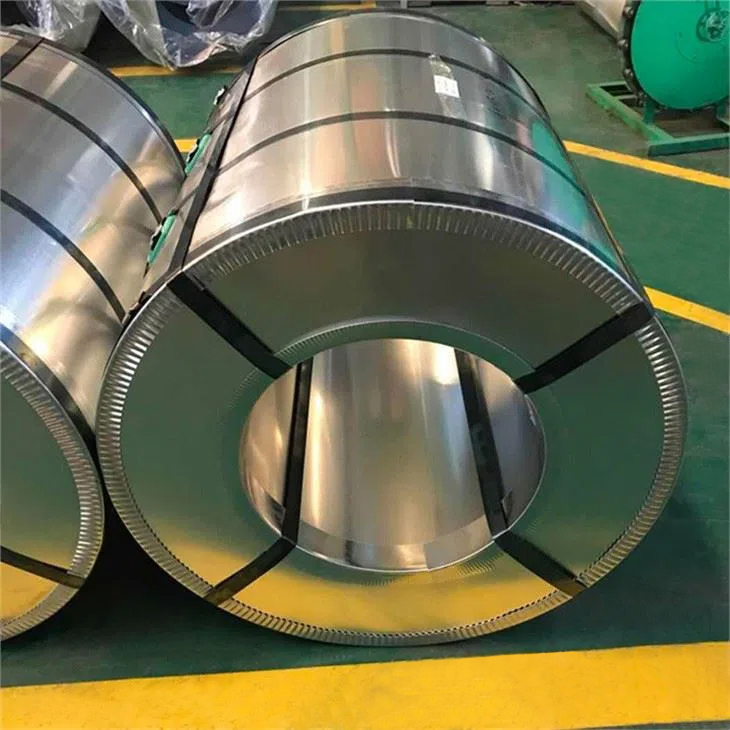

| Product Name | HC260Y Cold Rolled Steel Coil |

| Standard | GB/T、JIS、ASTM、DIN |

| Grade | DC01 |

| Width | 600-2050mm or as buyer’s requirement |

| Thickness | 0.12-3mm |

| Coil Weight | 3-14 MT |

| Steel coil internal diameter | 508mm/610mm |

| Technique | Cold rolled |

| Tolerance | As the standard or as required |

| Application | Household appliance, automobile, machine etc. |

| MOQ | 25 MT |

| Packing details | Standard seaworthy export packing or as required |

| Delivery | Within 15 to 90 days, according to order quantity |

| Payment | T/T or L/C |

I'd like to know the price of this product,

click here to get best price

I'd like to know the price of this product,

click here to get best price

Detail

Send your product requirements to us