DC01 is a cold rolled steel, which is defined in the national standard GBT 5213-2008 cold rolled low carbon steel plate and coil. DC01 is ideal for deep drawing and resistant to static stress. It's known for its excellent forming performance, processing consistency and high rigidity. This grade can be used for simple forming work, for example Bending, embossing, beading and pulling are used.

Cold coil is made of hot rolled coil at room temperature and below the recrystallization temperature, including plate and coil, of which the sheet delivered is called steel plate, also known as box plate or plate; the long length and delivered in coil is called steel strip, also known as coil plate.

Production process:

Due to no heating, there are no pitting and scale defects in hot rolling. The surface quality is good and the surface finish is high. Moreover, the dimension precision of cold rolled products is high, and the properties and structure of products can meet some special requirements, such as electromagnetic properties, deep drawing properties, etc.

Performance: mainly made of low carbon steel, with good cold bending and welding performance, as well as certain stamping performance.

Production process:

Due to no heating, there are no pitting and scale defects in hot rolling. The surface quality is good and the surface finish is high. Moreover, the dimension precision of cold rolled products is high, and the properties and structure of products can meet some special requirements, such as electromagnetic properties, deep drawing properties, etc.

Performance: mainly made of low carbon steel, with good cold bending and welding performance, as well as certain stamping performance.

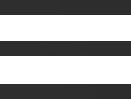

Features of cold-rolled steel coil :

1, cold rolled steel coil thickness more accurate, smooth surface, beautiful, but also has superior mechanical properties, especially machining performance.

2. The maximum thickness of cold-rolled steel coil is less than 0.1-- 8.0mm, such as the thickness of cold-rolled steel coil in most factories is less than 4.5mm;The minimum thickness and width are determined according to the equipment capacity and market demand of each plant.

3, cold rolled steel mill power, low rolling efficiency, and the rolling process in order to eliminate the work hardening have to carry out intermediate annealing, so the cost is higher, but cold rolled steel surface bright, good quality, can be used to process finished products, cold rolled steel is widely used.

1, cold rolled steel coil thickness more accurate, smooth surface, beautiful, but also has superior mechanical properties, especially machining performance.

2. The maximum thickness of cold-rolled steel coil is less than 0.1-- 8.0mm, such as the thickness of cold-rolled steel coil in most factories is less than 4.5mm;The minimum thickness and width are determined according to the equipment capacity and market demand of each plant.

3, cold rolled steel mill power, low rolling efficiency, and the rolling process in order to eliminate the work hardening have to carry out intermediate annealing, so the cost is higher, but cold rolled steel surface bright, good quality, can be used to process finished products, cold rolled steel is widely used.

Specification

| Product Name | DC01 Cold Rolled Steel Coil |

| Standard | EN10130 |

| Grade | DC01 |

| Width | 600-2050mm or as buyer’s requirement |

| Thickness | 0.12-3mm |

| Coil Weight | 3-14 MT |

| Steel coil internal diameter | 508mm/610mm |

| Technique | Cold rolled |

| Tolerance | As the standard or as required |

| Application | Household appliance, automobile, machine etc. |

| MOQ | 25 MT |

| Packing details | Standard seaworthy export packing or as required |

| Delivery | Within 15 to 90 days, according to order quantity |

| Payment | T/T or L/C |

I'd like to know the price of this product,

click here to get best price

I'd like to know the price of this product,

click here to get best price

Detail

Send your product requirements to us