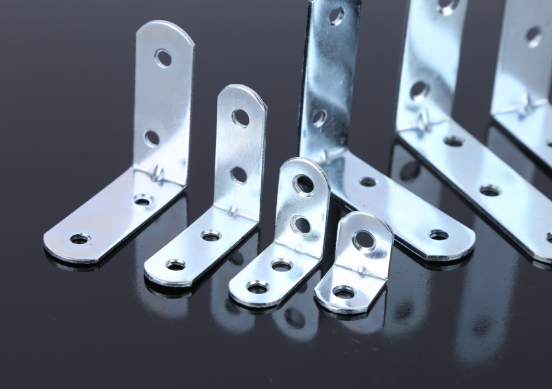

SECC electrolytic leaded galvanized steel sheet. N2: non environmental fingerprint resistant coating.

It is a stamping material, that is, zinc layer is plated on the surface of cold rolled plate. Rust and corrosion resistance. The price is quite high. The thickness of general plate is 0.4 ~ 3.2mm. The SECC surface is separately coated with oil secc-o, secc-n5, fingerprint resistance and secc-p phosphating.

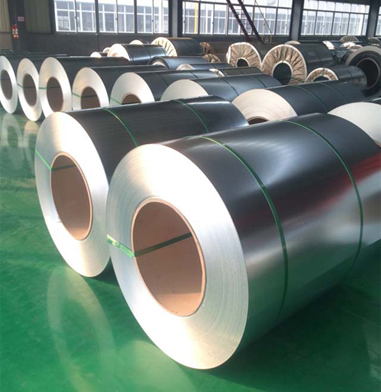

Main purpose:

Automobile: body plate, radio, fan, air filter, filter, fuel tank

Household appliances: refrigerator, washing machine, dryer, air conditioner, video recorder, CD player, color TV, tape recorder, microwave oven, stereo

Office machines: copiers, computer cases, printers, monitors, telex machines

Architecture: doors, walls, partitions, keels

Production machinery: agricultural machinery, industrial robot

Clean industry: operating room wall decoration

Others: distributor, oil storage tank, motor cover, steel furniture base plate

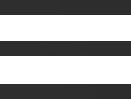

Specification

| Thickness | 0.2 mm-4 mm |

| Width | 600 mm-2,000 mm |

| Coil Weight | 3-5 tons (can be customized) |

| Surface Structure | Zero spangles, Small spangles, Regular spangles, Big spangles |

| Zinc Layer Thickness | 30g-275 g/㎡ |

| Standard | AISI, ASTM, BS, DIN, GB, JIS |

| Certificates | SGS, BV, ISO 9001 |

| Package | Standard Export Package |

Advantages

1.Available for customized specification on customers’ request.

2.Perfect Corrosion Resistance. The service life of galvalume is 3-6times as long as that of galvanized surface.

3.Perfect Processing Performance. Fully meet the requirement of roll processing, stamping, bending, ect.

4.Perfect Light Refelectivity. The ability of reflecting light and heat is twice that of galvanizing.

5.Perfect Heat Resistance. Galvalume products can be used at 315 degree Celsius for a long time without discoloration.

6.Excellent adhesion between the paint. Easy to paint and can be painted without pretreatment and weathering.

Galvanized Steel Coil Types

According to the processing method, we divide galvanized steel into the following categories:

1. Hot-dip Galvanized Steel Coil

As the name implies, hot-dip galvanizing is immersing the cleaned iron sheet into the molten zinc bath at about 500 degrees to form a zinc layer. It is the most commonly used method. It has some advantageous features:

1) The entire steel surface is uniformly covered with a zinc layer, even the corners, hollows, etc. so that the steel sheet is fully protected.

2) The cost of hot-dip galvanizing is cheap.

2. Electro-galvanized Steel Coil

Electro-galvanizing is a process of applying a layer of zinc to steel through electroplating, with a saline anode and steel conductor. It is able to enhance the corrosion and heat resistance of steel. Also, it makes steel sheets more good-looking.

Spangles

I'd like to know the price of this product,

click here to get best price

I'd like to know the price of this product,

click here to get best price

Detail

Send your product requirements to us